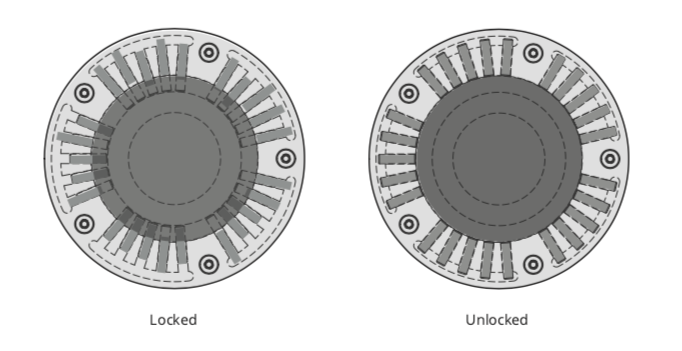

I'm a fan of lock boxes and other locking things that only require a bit of skill to unlock. I was inspired to explore this spinning unlock idea after watching this video. The concept is simple: pins move in and out of a pocket cut into a cylinder when jostling about - shaking the device will yield the sound of rattling pins, but won't unlock anything. A few pins are always engaged with the inside puck, no matter which way it turns. To unlock the inside puck, all of the pins need to flung outward quickly.

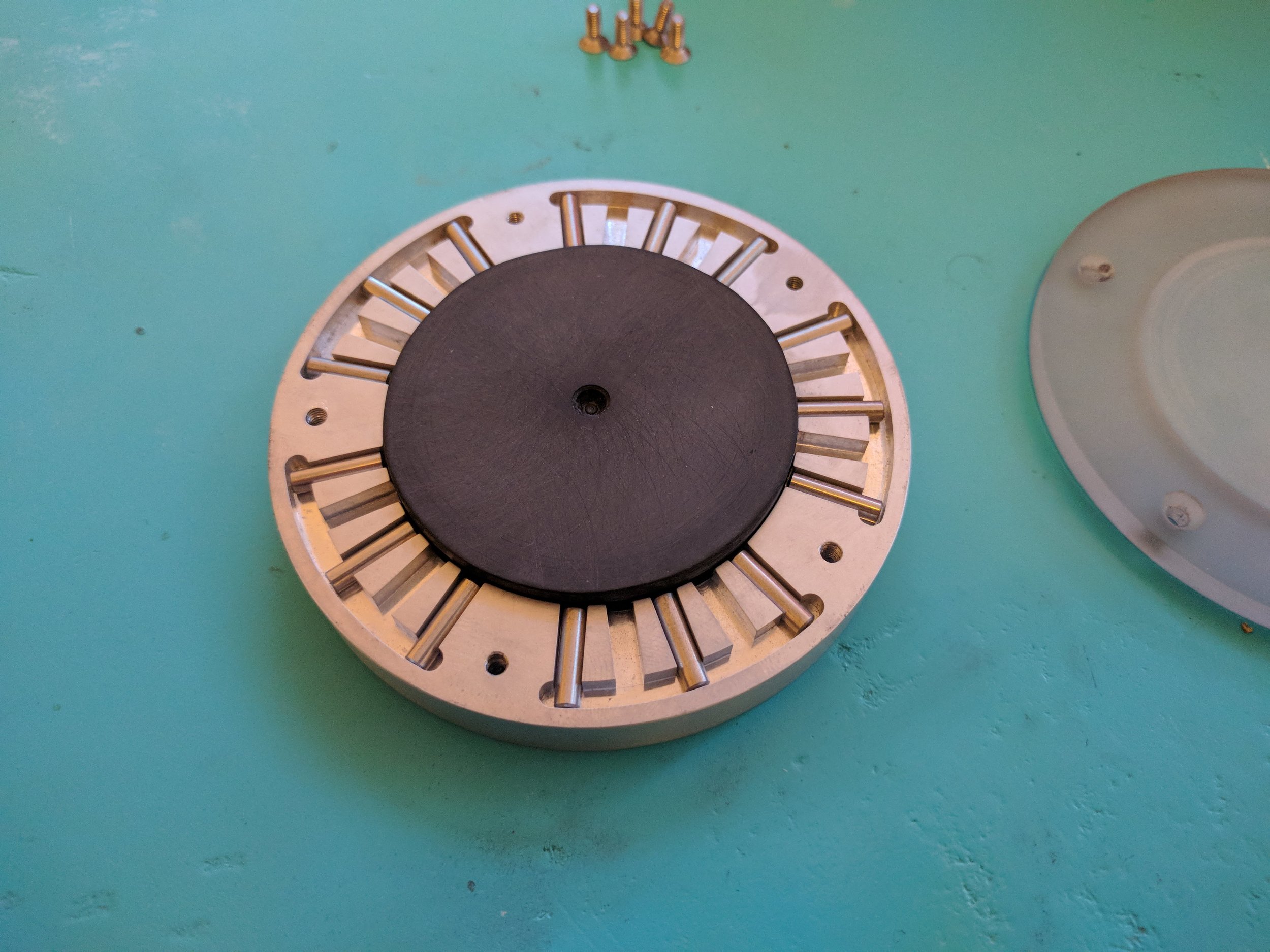

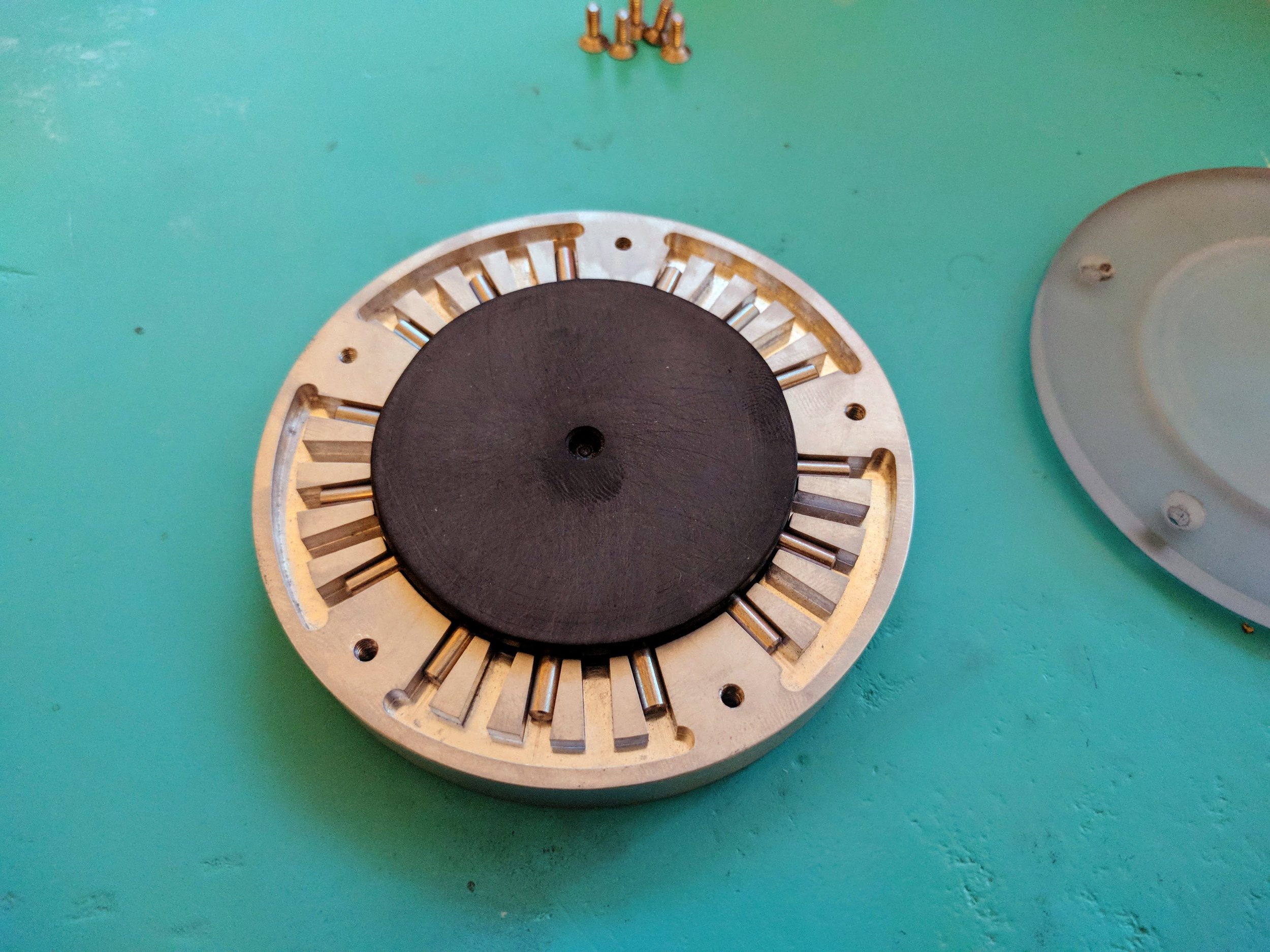

The below GIF shows how the pins fall into the black puck due to gravity, locking it in place. Because of this, the puck stays locked no matter which orientation the assembly is in, until it's spun.

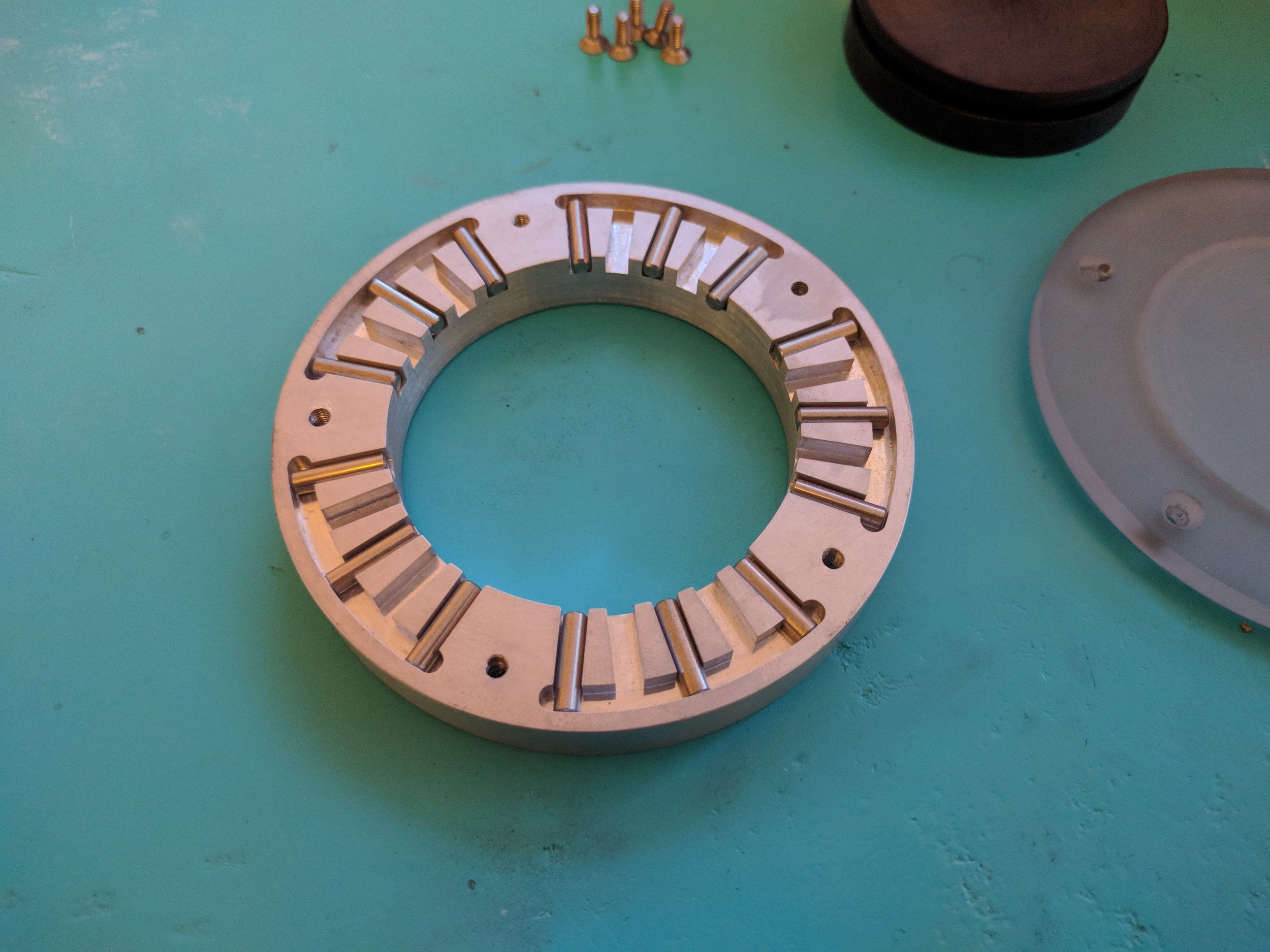

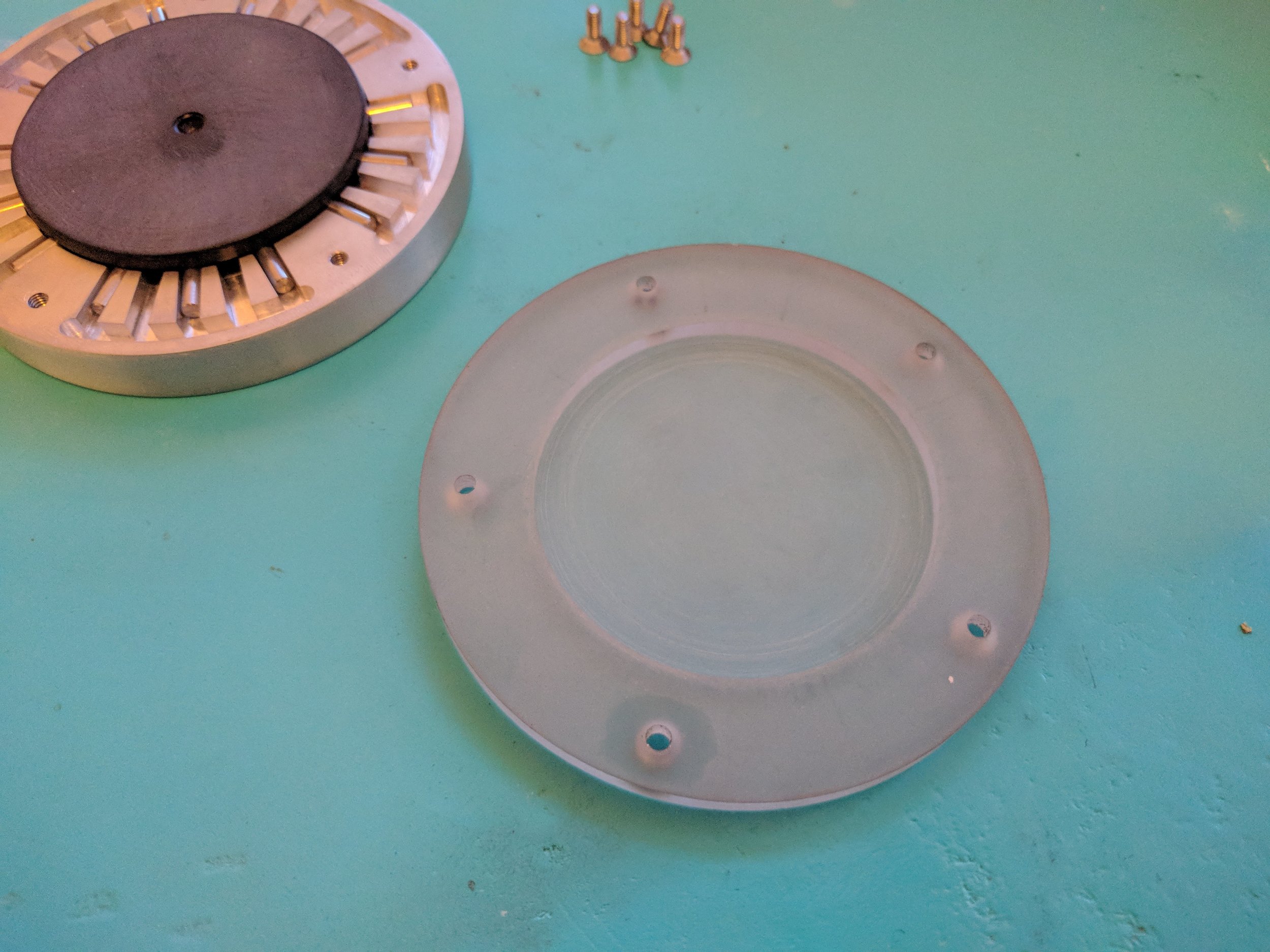

The small size of the assembly was determined mainly by the working volume in my Othermill. The machining of the aluminum and polycarbonate parts went fairly smoothly but took a long time - facing the aluminum to the correct thickness was particularly time-consuming. I'll be using another machine to do the facing in the future.

The intricate details of the aluminum base were perfect for the Othermill, however. I designed the five sets of pin channels in such a way that the 1/8" flat endmill could access all edges.

There are a few major improvements to make for the next version:

If this is ever going to become even remotely useful, the inside puck needs to have a compartment to store stuff in.

The screws shouldn't be so easily accessible.. sorta defeats the purpose of the lock. They'll have to go on the inside.

I need to figure out a manufacture-able and reasonably affordable method of keeping the pins inside the aluminum base when the puck thing isn't there.