The Arc Mouse from Microsoft is an affordable, battery-powered mouse that folds up for portability. Unfortunately, I recently lost the little USB dongle that came with mine, rendering it useless. I've seen the inside of a mouse before, but was intrigued by the fact that you can turn this one off just by folding it, so I took it apart to find out how it works. I initially thought the on-off feature was accomplished by a mechanical switch or contact inside, but I was wrong.

Unlike my last teardown, it was not immediately clear where to begin, as I couldn't see any screws during the initial inspection. So I started by gently prying up the thin plastic piece where your fingers rest, and surprisingly, it popped off with a satisfying click.

A look at the underside of the cover revealed two passive clips for retaining the part on the body of the mouse and some ejector pin marks - a sign of injection molding. Also note the two thin fingers protruding near the wheel cutout - these contact the momentary buttons for left and right mouse clicks.

At this point, I couldn't get any further without some serious destruction, so I went on a search for some screws to remove. Where could they be?

And this is where I learned something that I'll remember for future teardowns: screws are often hidden beneath rubber feet, stickers, and other adhesive elements. First, I removed the two rubber feet, revealing four phillips screws.

Hey look, more screws are hidden under the battery bay sticker! Admittedly, these took me far longer to find - I began cutting plastic away and only tore the sticker back after peeking inside and spotting some threads. Weirdly, the middle screw in the battery bay is the only non-Phillips one in the whole assembly - a T6 head.

The smaller folding portion of the mouse came off easily after removing two more screws. It's a pretty beefy hinge mechanism, made out of bent steel.

Now we're getting closer to see some PCB assemblies. But first, look at the size of this light pipe! It's responsible for making the only LED in the mouse, the on-off indicator, visible to the user.

After removing this piece, we finally get a nice look at the two PCBAs in the mouse. The bottom board is held in place with two small phillips screws (one of which is visible in the bottom left corner of the below photo), and the top board is prevented from moving side to side by a few plastic pins. Power is fed to the top board and the two are connected to each other via a single ribbon cable.

The mouse wheel itself is a single injection-molded piece. One side of the wheel sits on top of a momentary switch (for clicking the mouse wheel) and the other side, which has a hex profile, fits inside a little rotary encoder for recognizing scrolling.

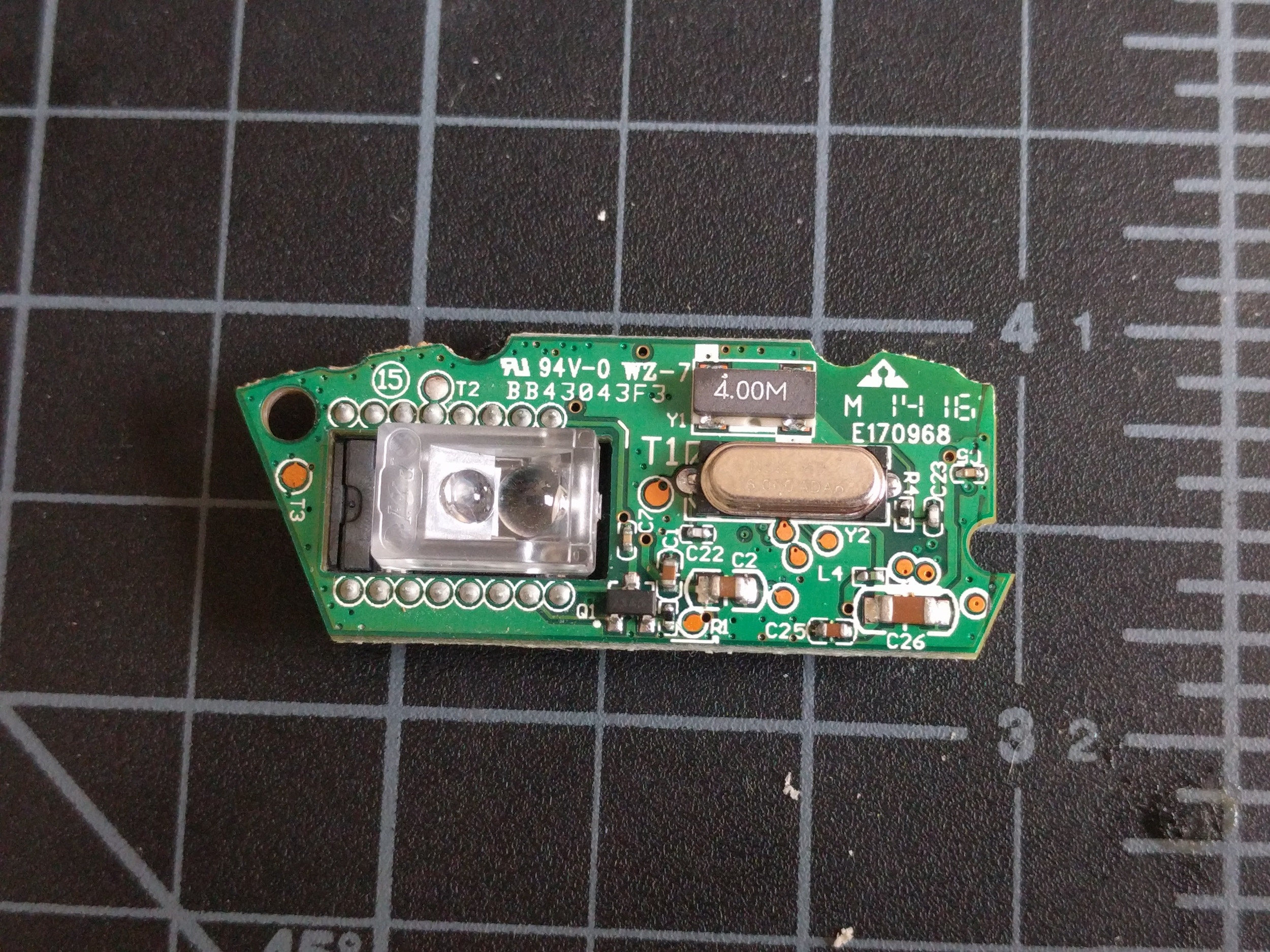

The bottom PCBA, seen above, includes the optical elements that point downwards and detect when the mouse is slid across a surface. This is the bottom side of the board - the opposite side includes some other elements, including a connector for the ribbon cable.

That giant cutout in the center of the top PCBA is for the mouse wheel, which sits between the rotary encoder (on the left) and on top of the mouse wheel click button on the right. In the above annotated photo, the two red buttons are for left and right clicking, while the orange button on the left is for the little button on the side of the mouse. The blue connector retains the ribbon cable that hooks up to the bottom PCBA.

Now that I was far enough into the disassembly to see the PCBAs, I realized how the mouse recognizes when it's closed - a tiny reed switch found on the backside of the top board. The magnet inside the folding section accomplishes two things: it holds the USB dongle in its pocket during transit and activates the little reed switch when the mouse is in the folded configuration.

With the folding section removed, I was able to replicate the on-off action with a few magnets. Note the green LED under the scroll wheel shut off when the magnet is near and slowly fade back in when it's removed.

I shouldn't be surprised - reed switches are extremely cheap and very reliable within their detection range, so if you can afford to use a magnet for actuating them, they're a great option. We use four of them in the Othermill to detect when the windows are removed.

Ok, another teardown in the books. I hope you enjoyed it. I learned a lot with this one and look forward to the next! Please comment below if you have anything that you'd like to share about this teardown that I didn't mention.