Fixturing is one of the most important parts of machining. Without good fixturing, your material is subject to vibration, which will not yield the best surface finish or the dimensions you want, and may even lead to tool breakage. I've recently found myself lazily leaving the Othermill's spoilboard in place and using tape for milling thick material, instead of switching to the more-rigid Precision Fixturing Set. So I set out to make the transition easier.

What is it?

The Quick-Change Bed is a modified Othermill Spoilboard that is not only functional for milling thin material under low load, but also very quick to remove, to give fast access to the mill's mini T-slot bed.

Why?

The typical time required to swap between the Spoilboard and Tall Alignment Bracket is at least a few minutes. This long setup time results in lazily using Nitto tape where a Toe Clamp should actually be used, yielding often-poor results. Reducing the time to swap fixturing will, in theory, lead to better parts.

Even though you lose some workable Z height with the Quick-Change Bed installed, it's not really a big deal - the bed encourages you to use the Spoilboard surface only for thin material, and the T-slot bed for anything else.

Here's how it's made:

There are two main components to the Quick-Change Bed:

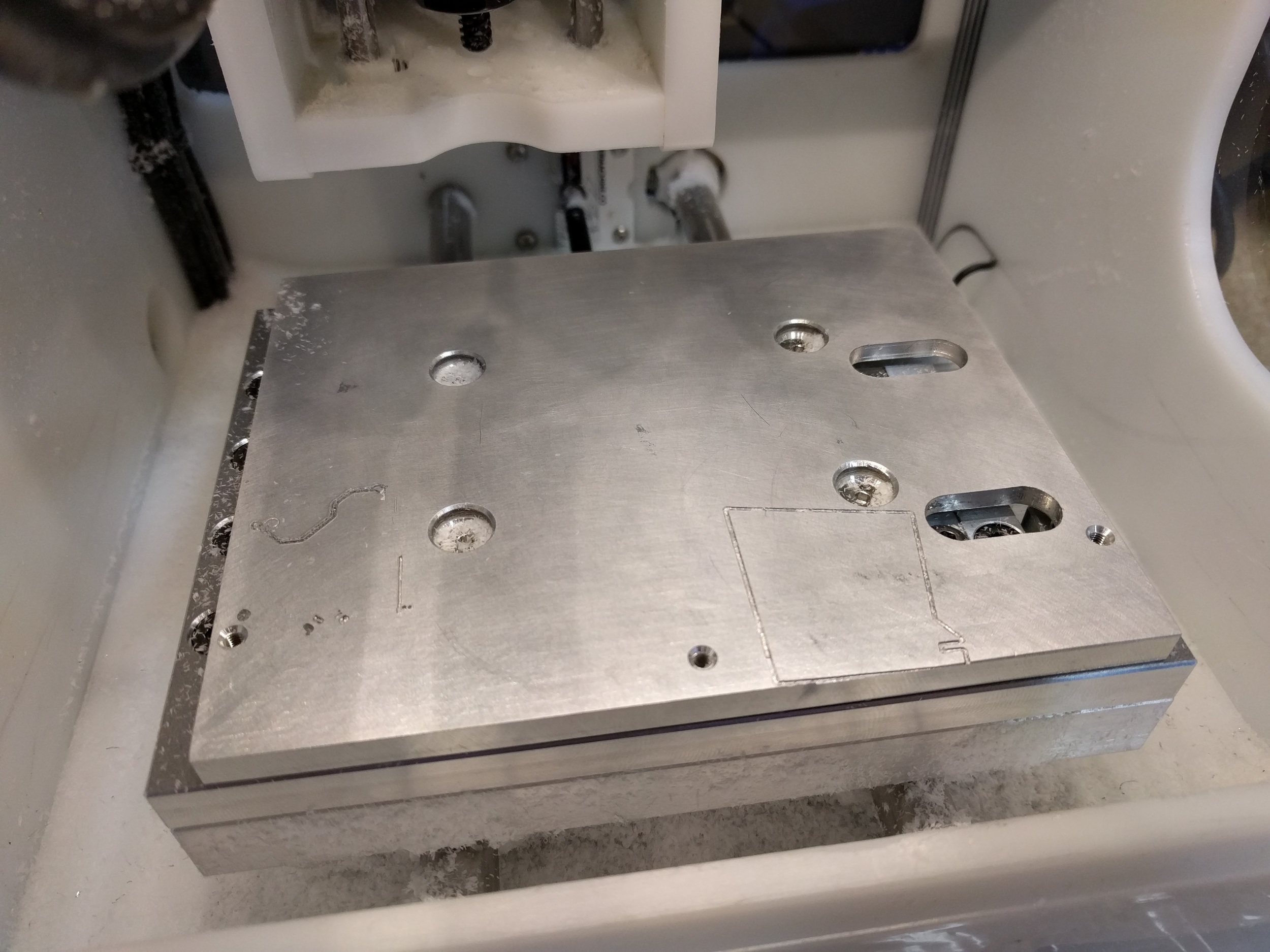

1. A modified Othermill Spoilboard, with slots for screw access and two pockets to give the Toe Clamp some room:

2. A spacer block that's milled to a precise size. It's attached to the modified Spoilboard with (4) M4 screws. This is the part that's actually held by the Toe Clamps:

Here's a video of the Quick-Change Bed in action:

It still needs work! Here's what I'd like to improve:

1. Make the spacer block out of aluminum, for strength and conductivity. With a Delrin spacer block, tool changes can only be accomplished by manually completing the conductivity loop between the Quick-Change Bed and the T-Slot bed.. this is not ideal. It will be nice to tap M4 directly into the block as well, instead of using press-in threaded inserts.

2. I'd like to modify the Toe Clamps and/or the spacer block to improve rigidity in the fixture. I'd like to try modifying Toe Clamps anyway, but with the caveat that they still have to be totally usable in every other situation, as I wouldn't want to have to remove them every time I needed to clamp something other than the modified Spoilboard.

3. The slots in the modified Spoilboard need to be a bit wider to accept the bolts that currently ship with the Precision Fixturing & Toe Clamp Set. I'd also like to shorten the length of the pockets on bottom of the Spoilboard - there's no reason for them to extend across the entire width of the part when clamping only occurs on one end.